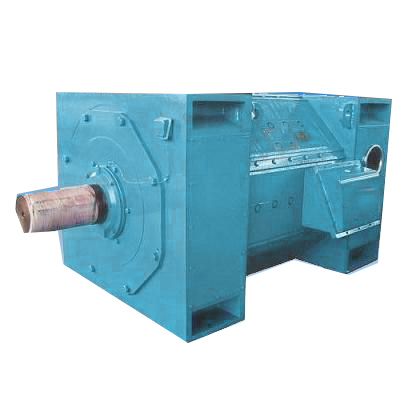

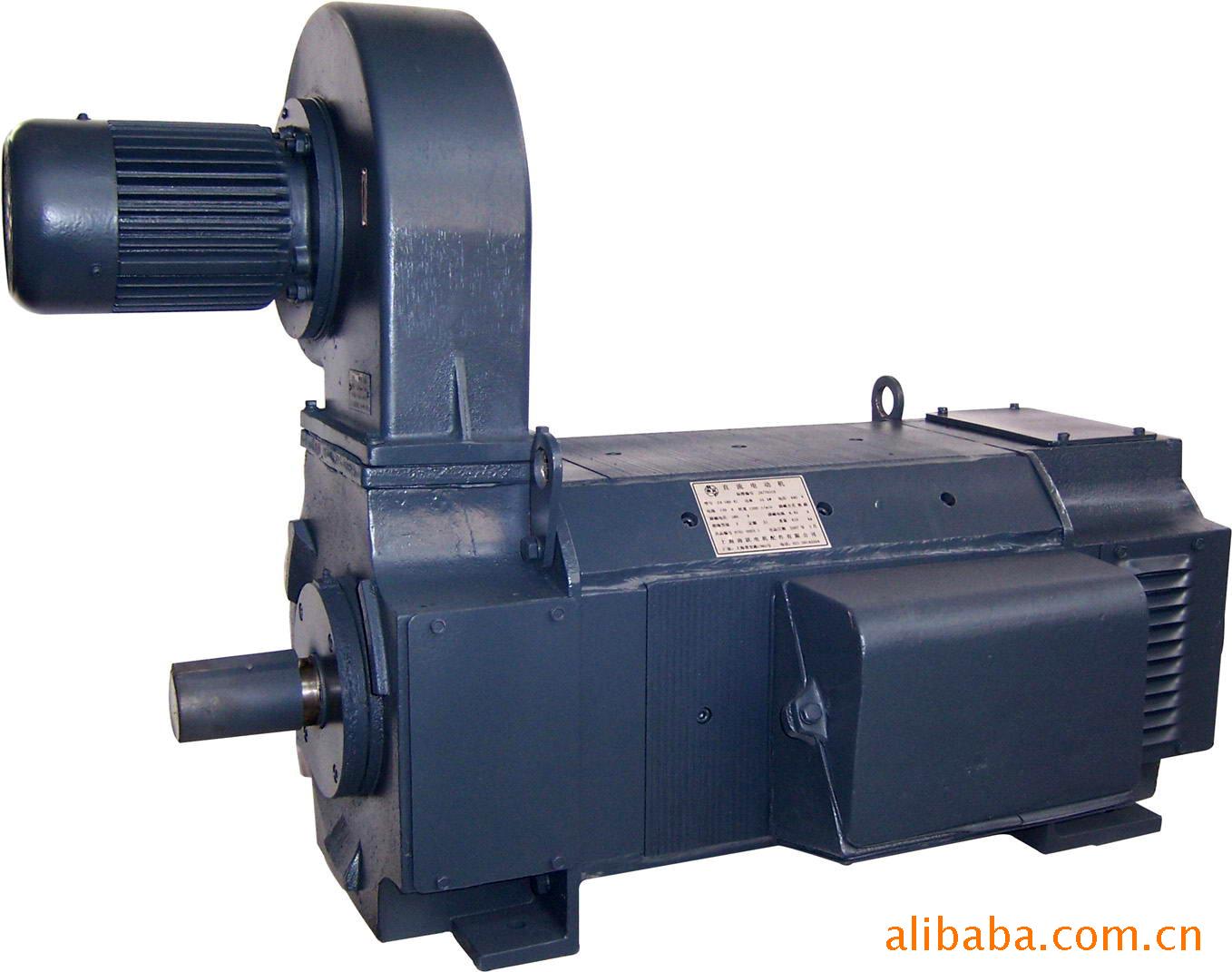

Features and use

The Z-series DC motor is a medium-sized DC motor developed by our company using the latest design and manufacturing technology. At present, the motor frame numbers of this series range from 315 to 710mm, with a power of 60KW-2000KW

The installation dimensions, performance, and technical requirements of this series of motors fully comply with JB/T9577 "Technical Conditions for Z-series Medium DC Motors" The relevant provisions in GB/T755 "Rating and Performance of Rotating Electrical Machines".

This series of DC motors is suitable for various types of mechanical transmission sources, such as the main drive of metal rolling mills, the main drive of coiling machine units, and sugar making and pressing machines

Main transmission, cement rotary kiln transmission, rubber and plastic extrusion machinery, etc

Document download

Z-series medium DC motor

- Brand PINNXUN

- Frame center height 315-710MM

- Voltage range 220V、330V、440V、550V、660V、750V

- power range 60KW-2000KW

- Installation method IM1001、IM1002

- Cooling method IC06、IC71、IC37、ICW37A86

- Bearing Brand SKF,FAG,ZWZ

- Protection IP23,IP44,IP54,IP55

- Insulation class H、F

- Lubricating grease grade No. 3 lithium grease or lubricating oil

- Material/size of junction box Metal material, customizable size

- Cable size According to the current size or customer requirements

- temperature sensors Pt100 (6 estatores, 2 rodamientos)

- space heater including

- delivery time 60 working days

- Warranty period 12 months

-

Specification

- Basic technical requirements for large DC motors used in rolling mills JB/T 6518-2005

- Test procedure for direct current machines GB/T 1311-2008

- Test specification for inter turn insulation of armature windings in DC motors GB/T 22716-2008

- Backpack type air water cooling device for AC and DC motors JB/T 8992-1999

- Quality classification of large DC motor products JB/T 56086-1996

- Technical specifications for working rolls of large forged alloy steel and aluminum rolling mills JB/T 13378-2018

- Technical specifications for marine DC motors GB/T 25292-2022

- Technical specifications for forged shafts of AC and DC motors JB/T 1271-2014

-

Features and use

The base of this series of motors adopts a thin steel plate polygonal laminated structure, which has the advantages of small volume and light weight. Suitable for thyristor rectifier power supply, under load current

Under rapid changes, the motor has good commutation performance. The entire stator and rotor are treated with solvent-free paint vacuum pressure impregnation (VPl), which gives the winding good moisture resistance and mechanical strength, as well as insulation and thermal conductivity, with excellent performance. The armature core is made of stacked silicon steel sheets and has good magnetic conductivity. All motors in this series adopt rolling bearings and a non-stop refueling structure. The insulation level of this series of motors is F level, and H level can also be produced

The installation type of this series of motors complies with GB997 and IEC34-7 "Motor Structure and Installation Type Code".

The performance of the motor

- Working altitude 0-1000m

- ambient temperature -30℃-40℃

- working duty S1、S2、S3、S9

- Temperature rise limit of winding and commutator 75K/85K

Order information

Environmental temperature: -15 ℃~+40 ℃

Altitude: not exceeding 1000M

Working mode: S1/S9

Service coefficient: 1.0 (customizable according to requirements)

Axial thrust: None

Corrosion protection requirements: None

If you have the following special requirements, you can contact sales or leave us a message:

1. Customized motor color

2. Dual/multi winding configuration

3. Imported bearings such as SKF/FAG/NSK

4. The protection level can be increased to IP56 and IP66

5. Installing an encoder

6. Install vibration sensors

7. Special installation dimensions and base customization

8. Provide insulated bearing design

9. Special anti-corrosion requirements such as WF1, WF2, C1-C5, etc

Download

Download

ENGLISH

ENGLISH

中文

中文

FRENCH

FRENCH

GERMANY

GERMANY

ITALY

ITALY

RUSSIAN

RUSSIAN

ARAB

ARAB

SPAIN

SPAIN

Download

Download