Features and use

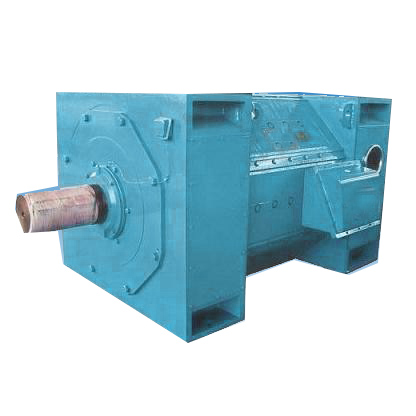

ZZJ-800 series rolling auxiliary drive motor is the main product of our factory, is a reference to the international Electrotechnical Commission IEC-34-13 "rolling mill auxiliary transmission motor" standard, is an important power equipment in the steel industry, in the working environment, can withstand frequent start, braking, frequent reversible, repeated large overload torque, mainly used in working roller, pressure device, can set tension roller, shear machine, clamp crane and other equipment, is ZZZ / ZZK, ZZZZY, ZZJO, ZZJ 2 series of motor updated replacement products.

This series of motors maintains the appearance installation size of the 600 series, and the power level is one level higher than the 600 series, which is comparable to the international advanced level.

The insulation grade of the motor is F, and reliable insulation structure and impregnation process are adopted to ensure stable insulation performance and good heat dissipation.

The motor is adapted to the power supply of the DC generator set, and also adapted to the static rectifier power supply, which can withstand the sharp change of pulse current and current (steel load change), and the change is good. When the rectifier power supply is connected according to the three-phase full control bridge line, it can run well for a long time without the filter reactor.

Document download

ZZJ series DC motors for large rolling mills

- Brand PINNXUN

- Frame center height 800-1000mm

- Voltage range 220、440V、550V、660V、750V

- power range 500kw-4000kw

- Installation method IM1001、IM1002

- Cooling method IC06、IC71、IC37、ICW37A86

- Bearing Brand SKF,FAG,ZWZ

- Protection IP23,IP44,IP54,IP55

- Insulation class H

- Lubricating grease grade No. 3 lithium grease or lubricating oil

- Material/size of junction box Metal material, customizable size

- Cable size According to the current size or customer requirements

-

Specification

- Basic technical requirements for large DC motors used in rolling mills JB/T 6518-2005

- Test procedure for direct current motor GB/T 1311-2008

- Test specification for inter turn insulation of armature windings in DC motors GB/T 22716-2008

- Backpack type air water cooling device for AC and DC motors JB/T 8992-1999

- Quality classification of large DC motor products JB/T 56086-1996

- Technical specifications for working rolls of large forged alloy steel and aluminum rolling mills JB/T 13378-2018

- Technical specifications for marine DC motors GB/T 25292-2022

- Technical specifications for forged shafts of AC and DC motors JB/T 1271-2014

-

Features and use

1. Protection and installation structure of the motor:

a. The entire series of protection forms: fully enclosed type is IP44, ventilated type is IP23

b. The installation method complies with the international GB997-81 regulation as IMB3. Other installation methods and methods can be separately agreed with our company.

2 Cooling methods:

There are two types of fully enclosed motors: IC0040 with natural cooling on the surface of the casing and IC0041 with air cooling driven by the internal fan itself.

There are three types of ventilated motors: IC17 with ducted air inlet, IC17 with natural air outlet, IC37 with ducted air outlet, and IC16 with independent blower.

The required cooling air volume for various seat numbers is (see table)

Machine seat number

External ventilation continuous rated air flow rate M3/S

机座号

外通风式连续定额时空气流量M3/S

802A

0.052

802B

0.052

802C

0.076

803

0.094

804

0.12

806

0.16

808

0.20

810

0.25

812

0.35

814

0.42

816

0.57

818

0.75

The position of the 3 output boxes, viewed from the main transmission end, is on the right side of the machine base. If necessary, the left or upper side will be separately agreed with our company.

The 4 motors can be equipped with a speed measuring generator and accessories, as well as a secondary drive end.

The 5 motors are double tapered shaft extensions, with a standard taper of 1:10. If a shaft extension taper of 1:9 is required or the total length of the motor changes, it can be negotiated separately with our company.

The transmission of the 6 motors is connected by elastic couplings, and the unit must be carefully aligned for coordination.

The performance of the motor

- Working altitude 0-1000m

- ambient temperature -30℃-40℃

- working duty S1、S2、S3、S9

- Temperature rise limit of winding and commutator 75K/85K

Order information

If you have the following special requirements, you can contact sales or leave us a message:

1. Customized motor color

2. Imported bearings such as SKF/FAG/NSK

3. The protection level can be increased to IP56 and IP66

4. Install an encoder

5. Install vibration sensors

6. Special installation dimensions and base customization

7. Provide insulated bearing design

8. Special anti-corrosion requirements such as WF1, WF2, C1-C5, etc

Download

Download

ENGLISH

ENGLISH

中文

中文

FRENCH

FRENCH

GERMANY

GERMANY

ITALY

ITALY

RUSSIAN

RUSSIAN

ARAB

ARAB

SPAIN

SPAIN

Download

Download